Flour packaging wrapping solution

Basic Info

Model No.: PALLETIZER AND T1800FZ-PL

Brand: Sinolion

Applicable Industry: Apparel

Usage: Produce Packing Belt

Packaging Material: Film

Packaging Type: Bag

Driven Type: Electric

Type: Packaging Production Line

Function: Transport Packaging

Packaging Technology: Moisture Proof Packaging

Application: Hair Care Products

Soft and Hardness: Semi-Rigid Package

Circulation Function: Outer Packing

Frequency of Use: Several Packaging

Mode of Operation: Domestic Product Packaging

Additional Info

Packaging: Steel wooden cases

Productivity: 1800 sets/ year

Transportation: Ocean,Land

Place of Origin: China Shandong

Supply Ability: 1sets /120 days

Certificate: ISO /CE

HS Code: 84224000

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Product Description

I. Technical introduction

Working flow:

The lift Conveyor helps to transport the bag - ABB robot stacking high -3 pallets are ready -

wrapping on the pallet with Turntable wrapper-UnLoad pallet onto conveyor by forklift

1. Auto turntable stretch wrapper

Technology data:

| Max load size(mm) | 1200 (L)×1200(W)×2400(H)mm |

| Packing efficiency | 20 loads / hour |

| Turntable speed | 0-12rpm |

| Height of turntable | 500mm±100mm |

| Power supply | 380V 60HZ 3Phase |

| Max load capacity | 2000kgs |

| Wrapping requirement | Bottom wrapping up to 2/3 of pallet, top wrapping 15cm higher than the height of pallet |

| Working ambiance | Indoor, normal temperature |

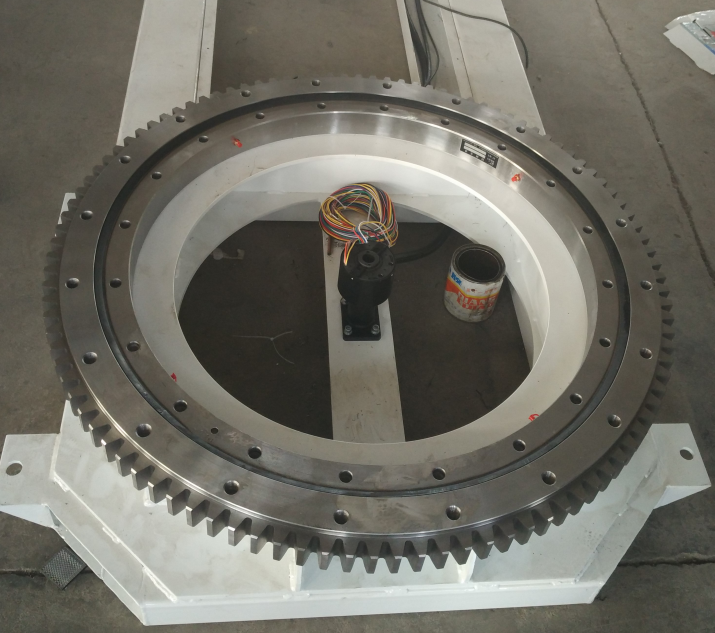

| Turntable | Diameter: 1800mm |

| Mast height | According to the pallet and turntable height |

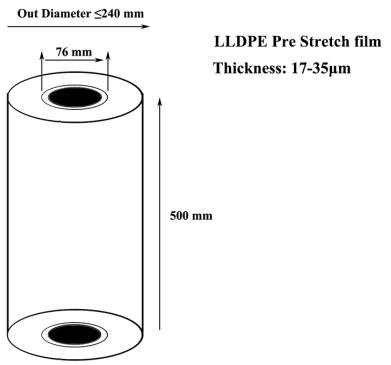

1. Wrapping material film

2. Utility:

Compressed air

Pressure: 0.5-0.6 MPa

Dew point: +2-+10℃ (7bar, +2-+10℃)

Air consumption: 1000ml/min

3. Supply scope

4.1 rotating turntable 1set

Turntable diameter: 1800mm

Roller dia.: 76mm

Distance between rollers: 119mm

Slew bearing driven, motor: SEW

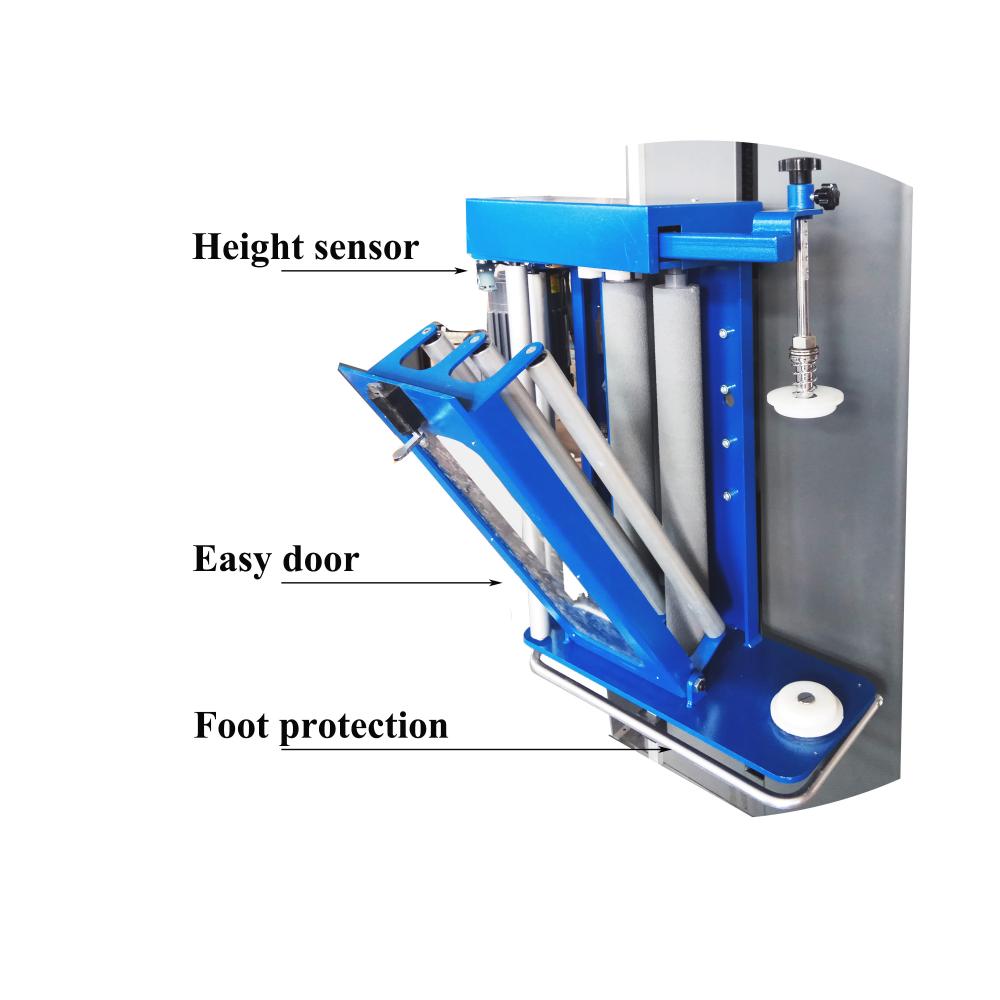

4.2 mast with film carriage 1 set

Film carriage lifting driving: chain driving, good stability and high reliability

Driving reducer: worm gear reducer

Open-door type film carriage

Motor brand: Chinese brand; power: 0.37kw

4.3 Film feeding & cutting device 1set

When stretch wrapping finish, the film will be cut and clamped automatically.

When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produced.

Film hot melt cutting adopts electrical heating wire to cut the film.

After film being cut, the brush go onto the film tail to make it smooth.

Pneumatic component: FESTO brand

4.4 control system 1set

PLC control system

Cut film automatically after wrapping finished

Film tension control adjustable

Carriage up/down speed adjustable

Safety tower light alarm

5. Main electrical parts

| Item | Brand |

| PLC, screen & inverter | Siemens |

| Touch screen | Siemens |

| Photoeye | Panasonic |

| Button & indicating light | APT |

| breaker | Schneider |

| Motor | Turntable: SEW |

| Pneumatic component | FESTO |

Spares:

| Item | unit | Qty | Remark |

| Film cutting heating wire | m | 5 |

|

| Hot sealing Tape | roll | 1 |

|

Product Categories : Project System