Fully-Auto Packaging Solution For Kitchen and Bath

Basic Info

Model No.: S1400

Brand: Sinolion

Applicable Industry: Apparel

Usage: Packaging of Goods

Packaging Material: Film

Packaging Type: Band

Driven Type: Electric

Type: Packaging Production Line

Function: Storage and Packaging

Packaging Technology: Moisture Proof Packaging

Application: Skin Care Products

Soft and Hardness: Semi-Rigid Package

Circulation Function: Outer Packing

Frequency of Use: Packing

Mode of Operation: Packaging of Export Products

Additional Info

Packaging: Standard seaworthy packing

Productivity: 1set/180days

Transportation: Ocean,Land

Place of Origin: China Shandong

Supply Ability: 1sets /180 days

Certificate: ISO /CE

HS Code: 84224000

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

Product Description

Project Introduction

This Packing Line is suitable for cupboards, cabinet, kitchenware, household appliances, etc.

Project System packaging process:The whole pallet goods enter the packaging line. The horizontal packaging machine first packs the goods in four directions. After wrapping, pallet comes to the automatic pallet packaging machine position to package on both sides, next, goods will be wait forklift to unload in turn.

Machine Introduction

1. Horizontal wrapper wraps tube or plate that won`t fit on a Turntable, require banding, compression or extra packing for shipment. It has a proven record of success in many industries such as profiled product, tubular product and plank stuff etc.We offer a wide variety of options to meet your specific requirements. Each application is evaluated to provide the right solution to your needs.

1.2. Specification

Rotating ring inner diameter:

1400mm

Wrapping dimension:

Width: 600-800mm Depth: 50-800mm Length: ≥1200mm Weight:

max.2000 kgs

Rotating ring speed

Max. 50-60rpm

Compressed air pressure

0.5Mpa Air consumption 10L/M

Motor power rotating ring:

2.2kw Conveyor: 1.1kw*2pcs 380V, 60HZ, 3phase

Stretch film

Width: 250mm;

Core size:

3``; Diameter: max 260mm

Thickness

14-35μm

Color Main machine:

Sinolion Standard

PLC electric control system, touch screen panel

Ring rotating speed controlled by the inverter

In-feed & out-feed conveyor speed controlled by the inverter

Start and finish cycles are controlled by photocells

Auto film cutting and conveying unit

1.4. Main configuration:

Item BrandPLC & interter: Omron

Motors: Chinese brand/SEW

Air parts :AIRTAC/SMC/FESTO

Circuit breaker : Omron

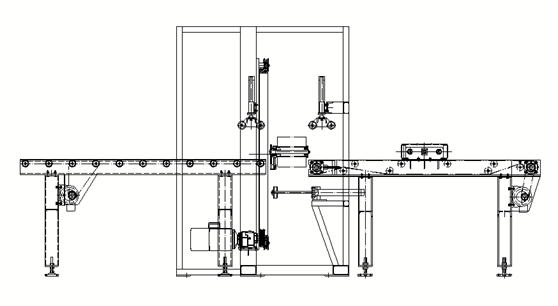

1.5. Diagram:

2. AutomaticTurntable Stretch Wrapping Machine T1800FZ-PL

2.1. Technology data:

Max load size(mm): 1200 x 1000 x 2400mm

Max .Packing efficiency : 30-40 pallets / hour

Turntable turning speed : 3-15rpm

Turntable diameter: 1800mm

Height of turntable: 450mm (To be confirmed)

Power supply : 380V 50HZ 3Phase (To be confirmed)

Max load capacity: 2000kgs

Color Moving parts: RAL 5010 other parts: RAL7011

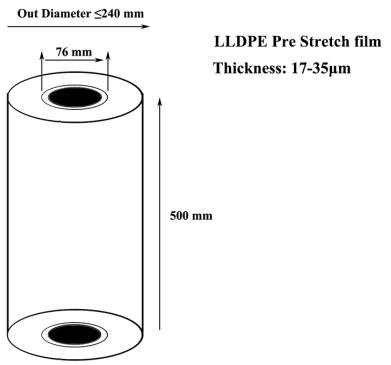

2.2. Wrapping material

Stretch wrapping film: Core size: 76.2mm

Stretch wrapping film: Core size: 76.2mmFilm width: 500mm

Diameter: max 260mm

Thickness: 14-35μm

2.3 Film carriage 1set

Powered pre-stretch system up to 1:3.5 to min film consumption(Pre-stretch ratio can be specially made )

Carriage door opens for effortless roll change and thread film

Film delivery variable speed by separate AC Drive Motor.

Heavy duty double-chain carriage lift, calm and safety.

2.4 Turntable 1set

Diameter: 1800mm

Roller dia.: 76mm

Centers: 119mm

Slew bearing transmission: shown as below

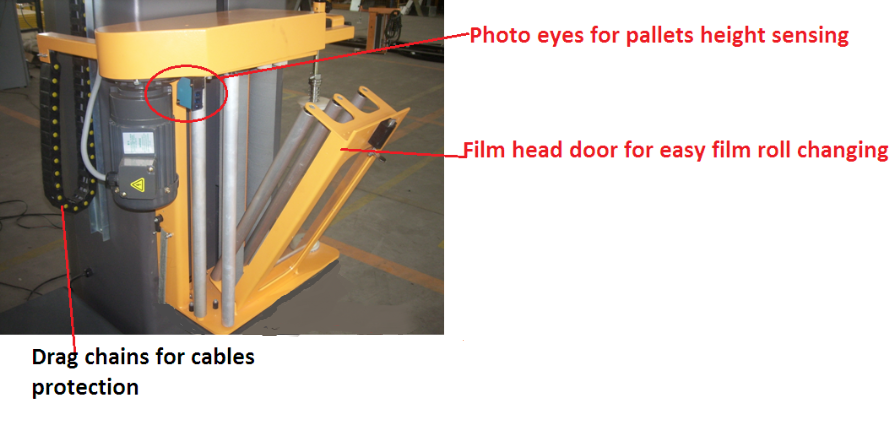

2.5 Mast with film head 1 set

Film carriage lifting driving: chain driving, good stability and high reliability

Driving reducer: worm gear reducer

Film head with door for easy film thread and film changing.

Motor brand: SEW; power: 0.37kw

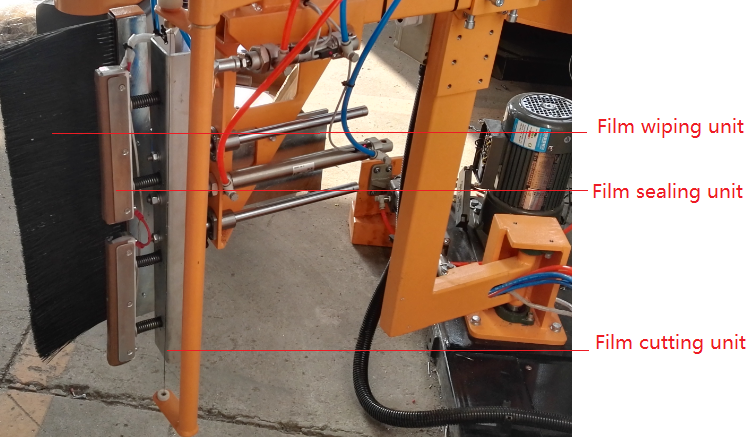

2.6 Film clamp& cutting unit 1set

When stretch wrapping finish, the film will be cut and clamped automatically.

When the film tail is released from the clamp, the air shooter will blow the film tail up, then the film tail will be wrapped by stretch film and keep it tightly with the pallet to ensure no film tail produced.

Film hot melt cutting adopts electrical heating wire to cut the film.

After film being cut, the hot sealer will seal the film tail automatically to ensure no film tail come out.

Pneumatic component: FESTO brand

2.7 Control system 1set

PLC control system

Cut film automatically after wrapping finished

Film tension control adjustable

Carriage up/down speed adjustable

Safety tower light alarm

2.8

No.

Item

Brand

Original

(1)

PLC& Inverter

Omron

Japan

(2)

Touch screen

Omron

Japan

(3)

Photo eye

Contrinex

Switzerland

(4)

Proximity switch

Omron

Japan

(5)

Air cylinder

Festo

Germany

(6)

Solenoid valve

Festo

Germany

(7)

Motors

SEW

Germany

(8)

Breaker

Schneider

France

(9)

Contactor

Schneider

France

Product Categories : Project System